Description

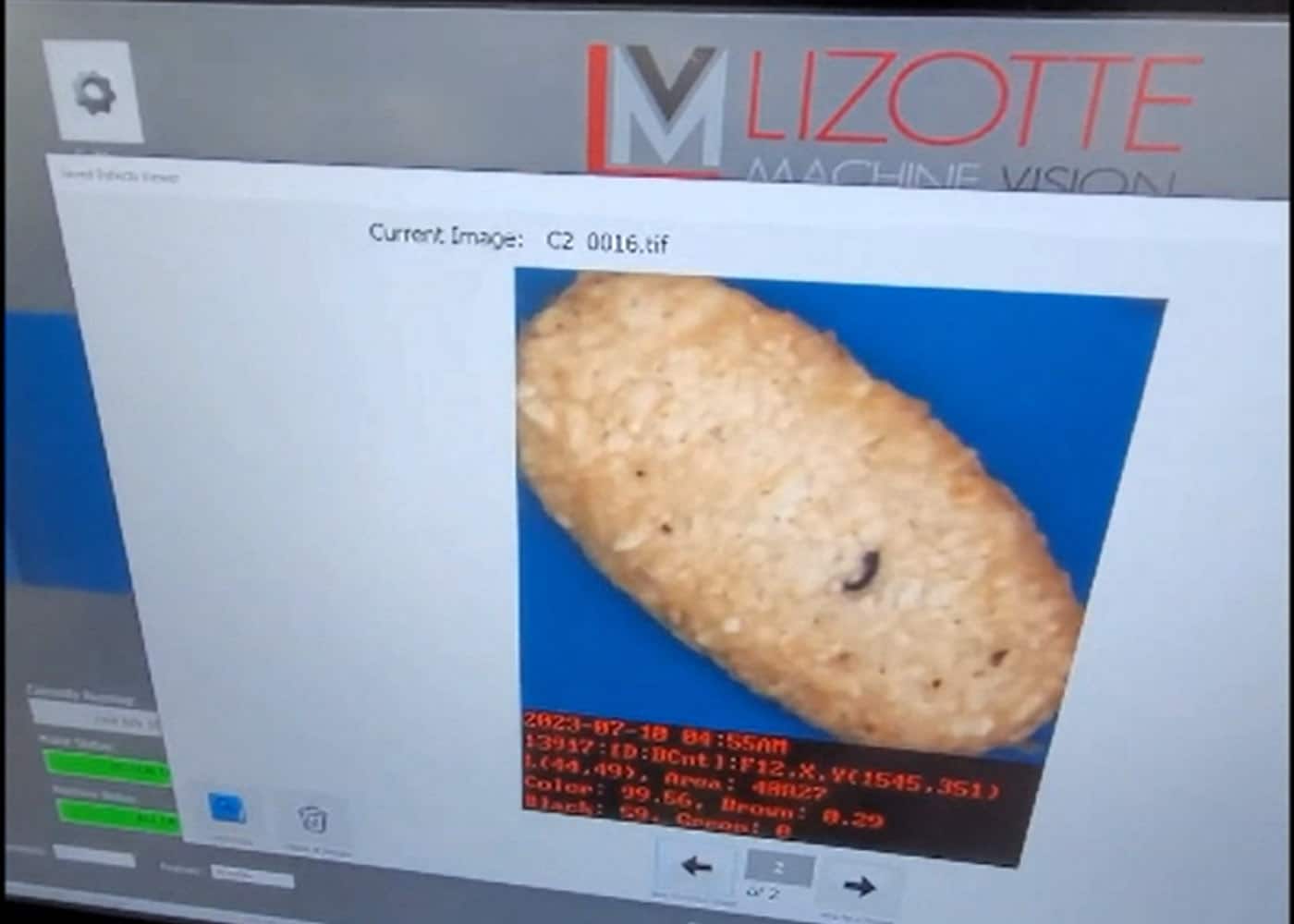

The Lizotte Hashbrown Sorter combines x-ray and color inspection to detect color, shape and foreign material defects. The x-ray inspection station will detect weight, glass, rocks, ceramic, stainless steel, ferrous and non-ferrous metal. On top of that, the color inspection will give the opportunity to detect low-density foreign material, brown/black spots, burnt pieces, broken patties and much more. This system will inspect up to 32 patties per second and will automatically eject defective products using an innovative ejection system performed by air-activated gates that do not damage the product. This technology can also be applied to other potato or fried products.

This system can inspect the product after the fryer, after the oven and after the IQF tunnel. It is possible to use it before or after the cooking process to remove the products from the processing line. With this kind of system, it’s easy to ensure total quality control on your processing line. This system is fully food-grade and ready for harsh wash-down environments.

Lizotte specializes in custom-built equipment. Hence, we would be pleased to supply a personalized system that would fulfill your operational requirements.

SPECIFICATIONS

- Rate up to 32 pieces per second

- Inspects for:

- Color

- Overcooked

- Undercooked

- Burnt spot

- Plastic, rubber, golf balls pieces, etc.

- Other color defects

- Shape

- Married

- Length

- Width

- Weight

- Foreign material

- Color

- Inspects various sizes and shapes on the same machine

- Can be used for after fryer, after oven or frozen product

- Robust wash-down stainless steel construction

- Independent of product size and orientation

- Operation is from the front panel touchscreen