Description

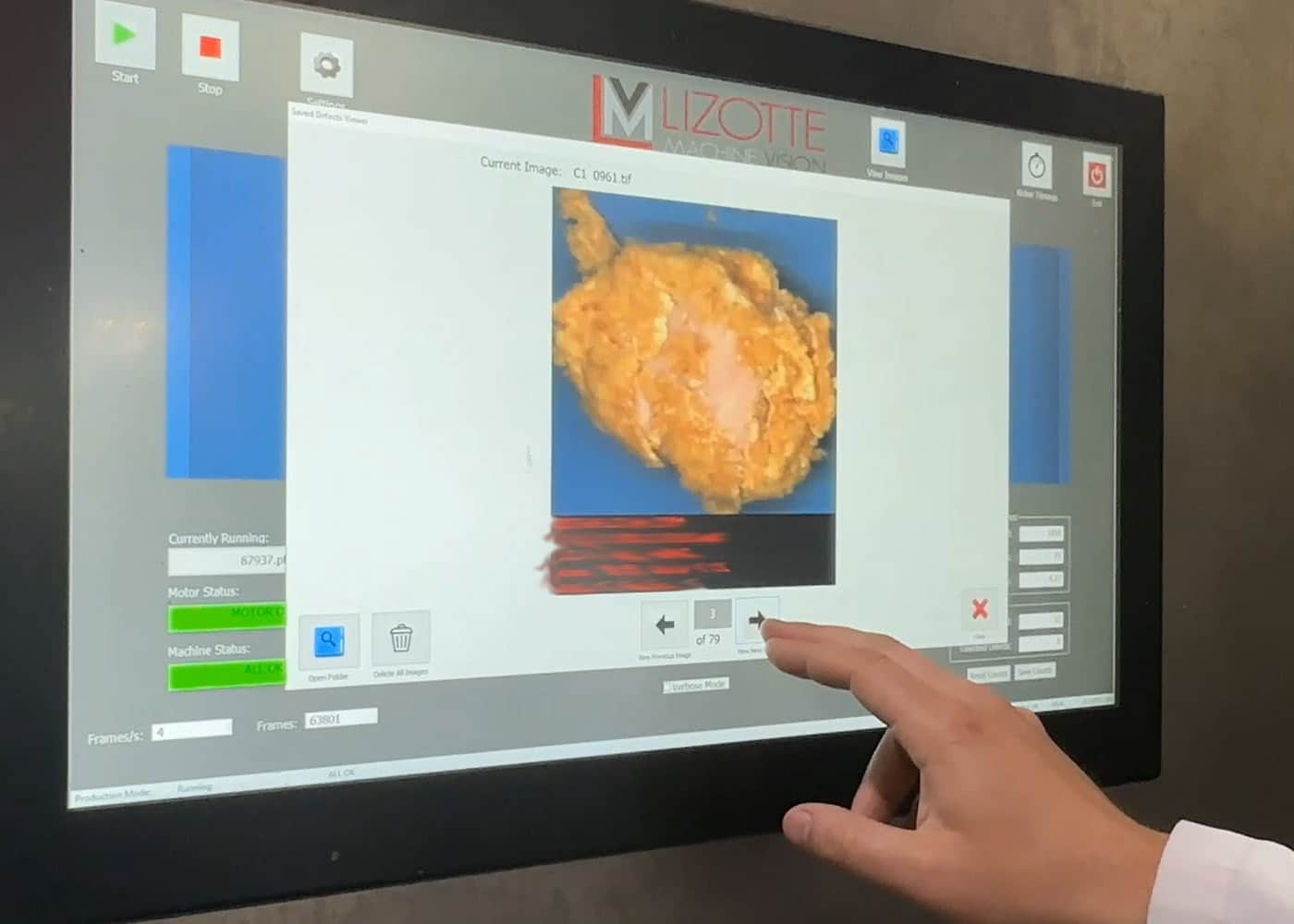

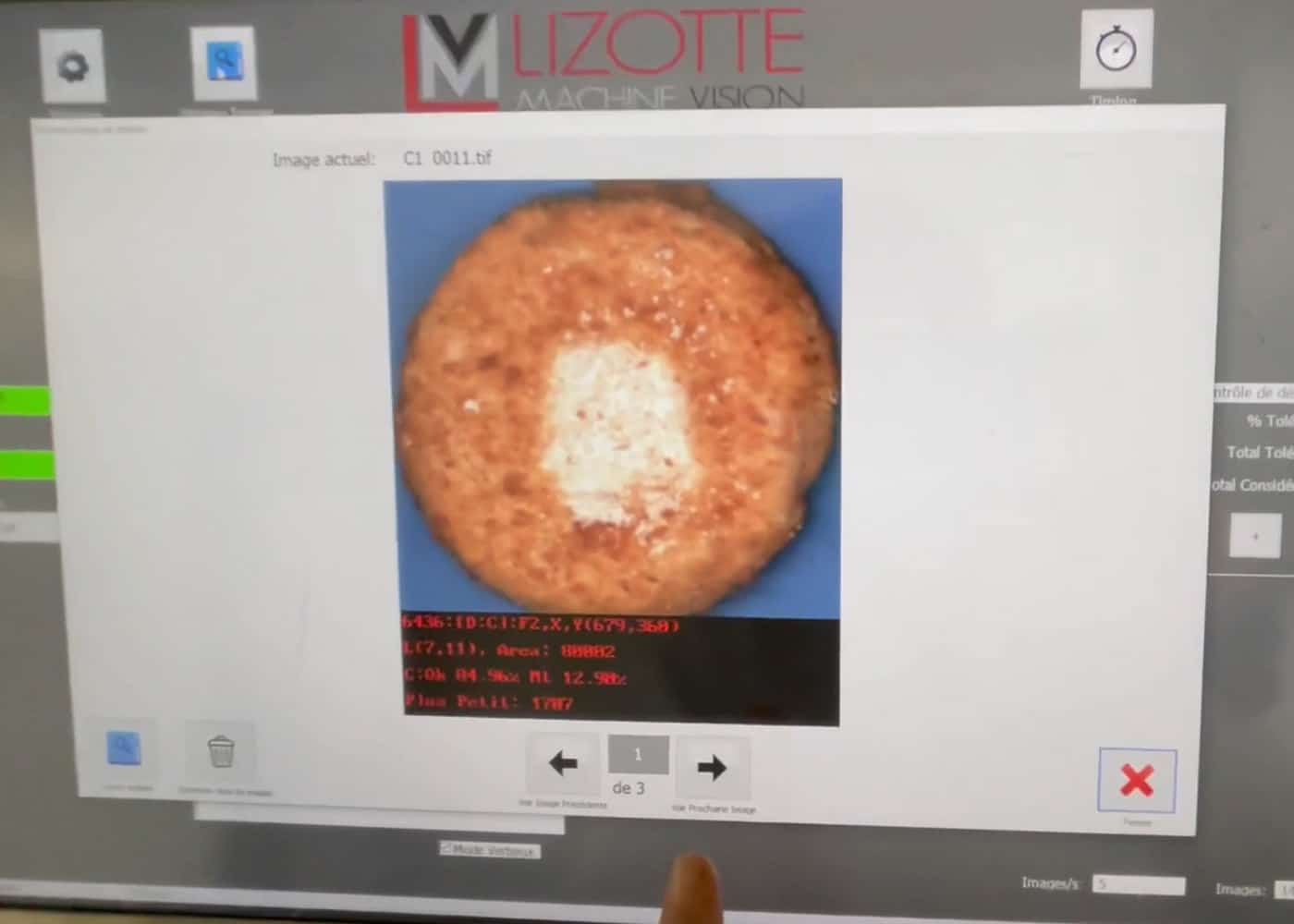

The Lizotte Port IQF Sorter uses line-scan imaging technology to detect missing batter, marriages, burnt spots, shape and low-density foreign material defects. It’s coupled with an x-ray inspection station to detect weight, bone, stainless steel and non-ferrous metal. This machine inspects up to 110 pieces per second and will automatically eject defective products using an innovative ejection system performed by air-activated gates that do not damage the product.

This system can inspect any type of frozen product of various shapes and sizes. It even possible to have the same technology post former or after the cooking process. With this kind of system, it’s easy to ensure total quality control on your processing line. This system is fully food-grade and ready for harsh wash-down environments.

Lizotte specializes in custom-built equipment. Hence, we would be pleased to supply a personalized system that would fulfill your operational requirements.

SPECIFICATIONS

- Rate up to 110 pieces per second

- Inspects for:

- Color

- Overcooked

- Undercooked

- Missing batter

- Excess batter

- Exposed meat

- Burnt spot

- Plastic, rubber, wood, etc.

- Other color defect

- Shape

- Married

- Length

- Width

- Weight

- Bone fragment

- Foreign material

- Color

- Inspects various sizes and shapes on the same machine

- Robust wash-down stainless steel construction

- Independent of product size and orientation

- Operation is from the front panel touch screen

- Optional x-ray for weight and foreign material detection