Description

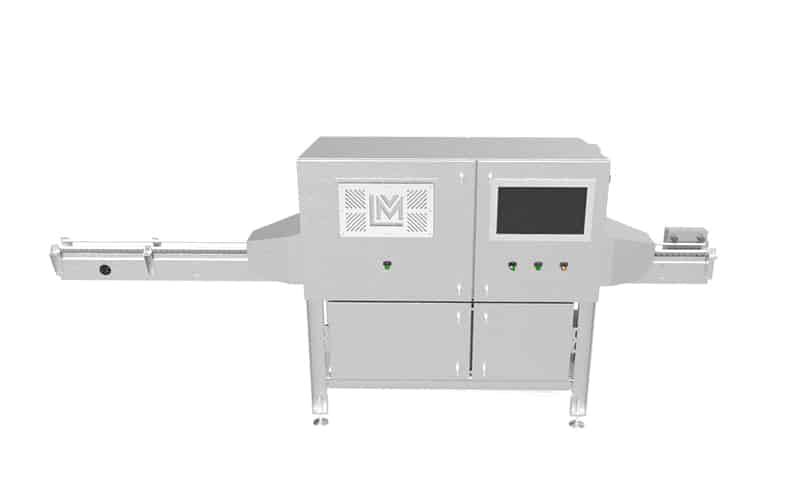

This innovative solution automatically ejects cans with seaming defects and/or internal foreign materials.

Seam inspection: The Lizotte Can Grader has been installed in many countries worldwide, to check the double-overlap closure seam on various can sizes and shapes. The grader acquires a perimeter view of the seam by using six synchronized cameras and a creatively designed lighting chamber. In the images, our specialized software finds the top and underside of the seam, and evaluates the seam for overall straightness, for width, and for variations in height, any of which could indicate a defect.

Inspection for Foreign Materials: Lizotte uses non-destructive x-ray to inspect tin cans of various sizes and shapes for internal foreign materials.

Lizotte specializes in custom-built equipment. Hence, we would be pleased to supply a personalized system that would fulfill your operational requirements.

SPECIFICATIONS

- Rate up to 1,200 cans per minute

- Seam inspection, foreign materials inspection or both

- Seam inspection:

- Droops

- Spurs

- Miss-chucks

- Knocked down flanges

- Other seaming errors

- Full parameter inspection

- Foreign materials inspection:

- Foreign materials in thin cans

- Weight inspection

- Automated ejection

- Production reports

- Operation is from the front panel touch screen

- Can provide shut down alarm to up-stream equipment

- Optional top-view stations to inspect rust, dents, and other defects

- Optional fully washable construction

- Optional weighting capability